Panel-Mounting / Installation of Hermetic Connectors"Backpack" Crimp-Contact Termination

Square-flange and box-mount hermetic-seal connectors require a seal between the connector and panel.

To minimize leak paths, machine the mounting panel with blind threaded holes. These blind mounting holes will prevent leakage between the internal and external environments. A gasket will seal the remaining surfaces. For optimized leak performance, the surface finish of the panel should be 16RMS or better.

- Hermetic Connector Pin / Pin and Socket / Socket Feedthrough Considerations

Sealing Square Flange Hermetic Connectors with Blind Mounting Holes

O-Ring Mounting Square Flange Hermetic Connectors

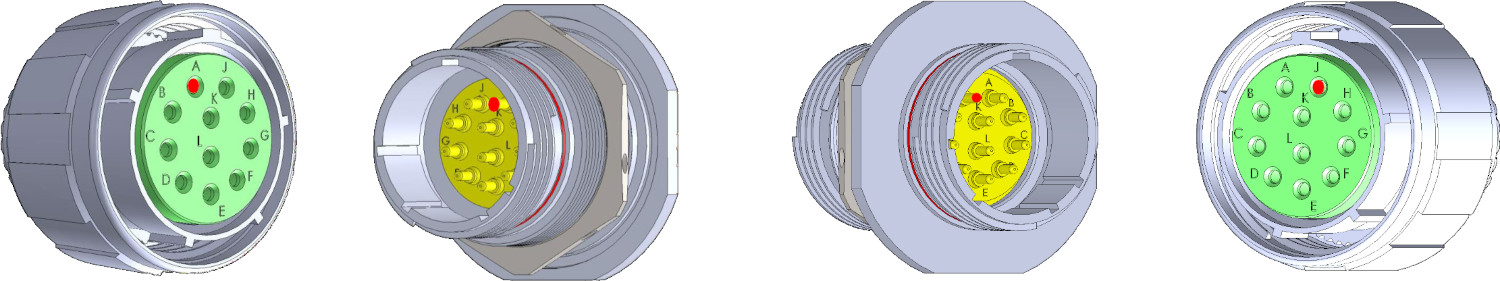

Crimp-contact termination of hermetic connectors with Glenair’s innovative "backpack" contact solution

Most hermetic receptacle connectors utilize solder cups and eyelet contacts. Termination of these contacts is a time-consuming and difficult process, even for highly skilled operators. Any error in termination can result in sub-optimal data throughput.

Glenair has designed a unique solution called a “Backpack” which allows wire termination with standard crimp tools and mil-spec style contacts—while maintaining robust hermetic sealing. This solution saves time and cost and improves the reliability of electrical connections in mission-critical applications.

Backpack-style contact terminations are available on Glenair signature hermetic connectors and mil-standard types including SuperNine D38999 Series III, Series 806 Mil-Aero, Series 80 Mighty Mouse, MIL-DTL-26482 and many others. Contact the factory or your local Glenair field sales representative for more information.