Micro-D connectors are a popular choice for space flight. Their small size and reduced weight, combined with excellent shock and vibration performance, has led to their widespread use on space vehicles. The Micro-Crimp connector brings the benefits of a crimp, rear-release contact system to the Glenair Micro-D family. Connectors can be terminated onto complicated, multi-branch wiring harnesses without splicing or soldering. Specifying a Series 79 Micro-Crimp connector for space flight may include NASA screening and outgassing processing (managed with simple mod codes) or material and plating selections such as the gold-plated micro-crimp connector shown above. See this page for the complete range of material and plating options.

Reference

- Poster - Contacts, Assembly Tools, Band-Master™ ATS

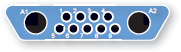

- Micro-Crimp Insert Arrangements

- Materials, Finishes, Specifications

- Performance Specifications

|

About Series 79 Micro-Crimp Shell Plating OptionsMicro-D connector shells are made of aluminum alloy and are coated to improve corrosion resistance. Electroless nickel plating is used for instrumentation, avionics and space applications where corrosion protection is not critical. Cadmium plating provides superior corrosion protection, but the United States Department of Defense (DOD)has mandated the elimination of cadmium from DOD weapons systems because of toxicity concerns. The European Union has also restricted the use of cadmium on electronics equipment (RoHS). |

|

Series 79 Micro-Crimp Connectors for Space Flight

|

Series 79 Micro-Crimp Recommended Panel Cut-Outs

|