Qualified Military and Commercial Hermetic Connectors for Harsh-Environment, Air-Tight-Seal Applications

Hermetic connectors are highly engineered Mil/Aero interconnect devices designed to maintain an air-tight seal in extreme environments. Using glass-to-metal sealing or advanced encapsulant technology, these hermetic seal connectors prevent moisture ingress, resist pressure differentials, and protect sensitive electronics in mission-critical systems. From submarines and oil-and-gas equipment to orbiting satellites, laboratory vacuum chambers and commercial or military aircraft, hermetic connectors ensure long-term reliability wherever environmental sealing is essential.

Glenair supplies a broad range of hermetic seal connectors — including MIL-DTL-38999 Series I, II, III, and IV — originally developed for military aerospace hermeticity requirements. Today, these ruggedized, air-tight connectors are also widely used in commercial sectors such as energy exploration, industrial instrumentation, and medical devices.

Engineered for extreme application conditions, Glenair hermetic connectors safeguard high-value payloads and electronics in environments characterized by severe weather, high altitude, rapid temperature changes, and vacuum exposure. Applications include sealed black-box enclosures, UAV payload systems, precision sensors, and other electronics that depend on consistent pressure-tight and moisture-barrier performance.

While glass-to-metal sealing remains the industry benchmark, Glenair’s next-generation CODE RED™ encapsulant hermetic technology offers mission-critical sealing with improved electrical performance and significant weight reduction — a major advantage in modern aerospace and unmanned systems.

Zero or Near-Zero Gas Leakage (Hermeticity)

Both Glenair CODE RED and glass-to-metal seal hermetic connectors deliver a qualified air-tight seal to prevent the passage of gases — not just liquids — through the connector interface. In Mil/Aero hermetic connectors, this is quantified using leak-rate limits such as:

- ≤ 1×10⁻⁷ atm-cc/sec helium

- Verified via helium fine-leak and gross-leak testing

- Rated operating temperatures -115°C to 200°C (-175°F to 392°F)

NASA Hermetic Standards

NASA Hermetic Standards

Glenair supplies hermetic feed-thrus and hermetically-sealed receptacle connectors that meet the following NASA standards for interconnects used in manned spacecraft:

- NATC (NASA Threaded Coupling)

- SSQ21635 (NASA standard for circular, mostly hermetically sealed connectors used in manned spacecraft)

- NASA-STD-8739 (NASA assembly standard for cable systems on the ISS, ESCC manufacturing standards are compliant)

Military Standard Hermetic Connector Configurations Include:

- Hermetic power inserts based on MIL-DTL-5015 in shell sizes 25L to 37

- Signal hermetic designs IAW MIL-DTL-38999 Series I, II, III, and IV

- Rectangular MIL-DTL-24308 hermetic receptacles

- MIL-PRF-83513 type Micro-D hermetic connectors

- MIL-DTL-26482 Series I and II type power and signal hermetic designs

- MIL-DTL-83723 Series III threaded and bayonet hermetics

MIL-DTL-38999 QPL and Glenair Signature SuperNine

Hermetic Seal Connectors

MIL-DTL-38999 Series I, II, III, and IV Hermetic Connectors

Glass-to-Metal Seal D38999 Hermetic Connectors

CODE RED encapsulant-seal D38999 Hermetic Connectors

Series 80

Mighty Mouse Reduced Size and Weight Hermetic Connectors

Micro Miniature Circular Hermetic Connectors (Glass-Seal and CODE RED) with Five Available Coupling Styles

Series 806

Mil-Aero Micro Miniature Hermetic Connectors

Micro Miniature Glass-to-Metal and Lightweight Encapsulant CODE RED Hermetic Connectors IAW MIL-DTL-38999 Series III

Geo-Marine® Series III Type Hermetic Seal Connectors

High-Density Hermetic Contacts. Miniature Glass-to-Metal Sealed Pin and Socket Contacts for Space and Military Use.

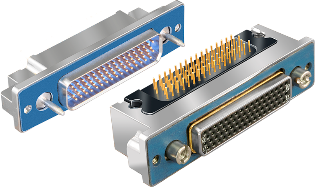

QPL Hermetic MIL-DTL-24308 D-Sub Connectors

QPL MIL-DTL-24308/9 and Glenair Commercial Hermetic D-Subminiature Connectors

MIL-DTL-83513 Type Micro-D Hermetic Seal Connectors

Kovar Shell Hermetic Connectors. Nickel-Cobalt Ferrous Alloy Hermetic Housings for Thermal Expansion Matching.

Micro-Crimp Hermetic-Seal Connectors

High-Density, High-Performance Hermetic Rectangular Bulkhead Feed-Thrus

Series 790 High-Density

Series 791 Scoop-Proof

Series 970 PowerTrip®

Hermetic-Seal Connectors

High-Ampacity, Harsh-Environment Hermetic Power Connector Capable of Meeting the Demanding Requirements of Modern Defense and Aerospace Systems

Series GRF

RF Hermetic Connectors

Jam-Nut Mount Bulkhead Feed-Thrus

BNC, TNC, SMA, and other RF Interfaces

MIL-DTL-26482 Series I and II Type

Hermetic-Seal Connectors

Power and Signal Hermetic Connectors with Fast and Reliable Bayonet Coupling

MIL-DTL-26500 Type

Glass-Sealed Hermetic Receptacles

Popular Connector Designs Superseded by MIL-DTL-83723

MIL-DTL-5015 Type

Hermetic Seal Connectors

AS50151 Space-Grade, Ultra-Reliable Glass Sealed Connectors for Satellite and Spacecraft Applications

CODE RED™ Lightweight Hermetic Sealing Connectors

"Mission-Critical" Hermetic Sealing with 1x10-7 Leak-Rate Performance, Lower Electrical Resistance and Lighter Weight

Glenair Worldwide Hermetic Capabilities

Military-Grade Hermetic Connectors: From Glendale to to Bologna

Glenair QwikConnect MagazineJanuary 2026Volume 30Number 1

- eBook

- PDF (Single pages, print friendly)

- Chris Toomey's Outlook Column: The True Cost of Ownership

Hermetic Leak Rate Testing Limits and Qualification for Connectors Used in Military and Aerospace Applications

Hermetic sealing is central to the long-term reliability of military and aerospace electronics. Hermeticity—defined simply as the condition of being airtight—prevents the ingress of moisture, outgassing products, and contaminants that can degrade electronics or lead to failure over the life of a mission.

Mil-Qualified and Glenair Signature Hermetic-Class Connector Datasheets

Introduction to Hermetic Seal Connectors

- Introduction to Glenair Hermetic Seal Connector Products

- Space-Grade Application Guidelines for Hermetic Connectors

- Hermetic Connector Helium Leak Rates and Testing

- Hermetic Connector Designer's Application Checklist

Hermetic Connector Modification Codes

PC Tail Termination Note

To prevent detrimental intrusion of cleaning solvents/water into the connector when terminating, the connector must be protected IAW IPC J-STD-001 and/or NASA STD-8739.3. For assistance and/or additional information, please contact factory.

Hermetic Connector Tech Tips: Application Notes on Mounting and Termination of Hermetic-Seal Connectors

- Sealing Square Flange Hermetic Connectors with Blind Mounting Holes

- O-Ring Mounting Square Flange Hermetic Connectors

- Crimp-contact termination of hermetic connectors with Glenair’s innovative "backpack" contact solution