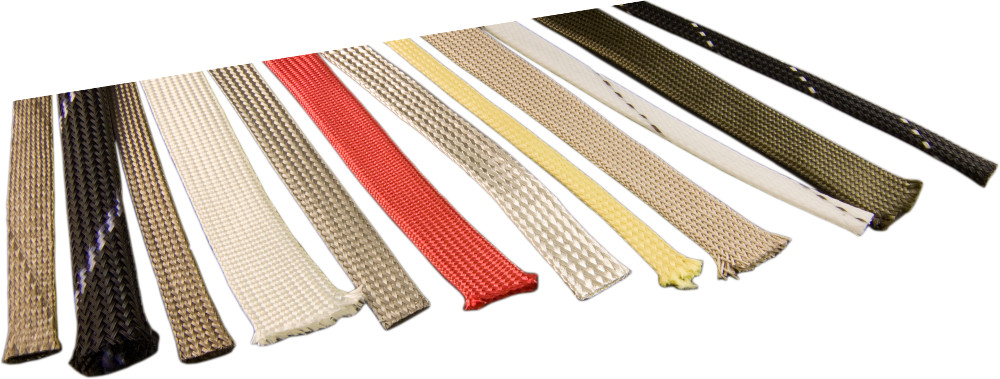

Glenair supplies the industry's broadest range of non-metallic tubular braid for abrasion protection and temperature shielding of wire bundles and cable harnesses in electrical wire interconnect systems. From economical monofilament Nylon, to high-performance bonded and unbonded Nomex®, these bulk tubular expandable braid products are shipped ready for immediate installation and application in high-performance wire protection applications.

|

Nextel™ 312 tubular braid is composed of 312 grade continuous fiber that offers strength and flexibility, even in constant high temperature environments. Its properties include low thermal conductivity and thermal shock resistance, making it ideal for applications that require a flame barrier or thermal shield. It outperforms other high temperature textiles like aramids and fiberglass.

|

|

Polyether ether ketone (PEEK) is a popular composite thermoplastic material with outstanding high-temperature resistance, crush resistance, and flexibility. PEEK is typically specified in applications that require optimized weight reduction as well as abrasion resistance and zero halogen content.

|

|

FEP tubular braid is one of many non-metallic material choices available from Glenair selected for its high lubricity, and as a result its excellent resistance to abrasion. FEP is a high temperature material well-suited for both military and commercial transport applications. This clear variant of the FEP material is typically specified for systems where a clean appearance and/or the ability to visually inspect sub-material layers is valued.

|

|

Non-metallic tubular braid, Kevlar®, earns much of its reputation for strength and abrasion resistance due to its construction from individual strands of yarn (as opposed to monofilament materials such as FEP and PEEK). 102-071 is Glenair's strongest non-metallic tubular braid material, and offers excellent resistance to caustic chemicals and fluids as well as wire interconnect protection at temperatures up to 160°C.

|

|

Multifilament Nylon is the workhorse of non-metallic tubular braid used for electrical wire interconnect system protection. It offers excellent abrasion resistance, general-duty resistance to fuels and chemicals, and is available in standard black or gray for identification of wire bundles. Nylon is an economical choice for most general-purpose applications.

|

|

Dacron® is similarly constructed to Glenair's 102-071 material. It is a multistrand yarn construction tubular braid with excellent tensile strength, durability and chemical resistance, albeit at a lower performance level compared to the costlier Kevlar.

|

|

Halar® is a self-extinguishing tubular braided sleeving used for mid-range temperature applications. Halar® is chemically resistant to corrosive liquids including organic solvents, and has been successfully applied to applications from nuclear power plants to premise wire interconnect protection systems.

|

|

General-duty abrasion-resistant unbonded yarn, Nomex® is well-suited for mechanical protection of soldier Personal Area Network cabling. Available in a broad range of colors, the soft, flexible, and durable material resists fraying and piling common to less robust yarns. In addition to improved flame resistance, unbonded braid, Nomex® offers superior flexibility compared to bonded solutions.

|

|

103-106 unbonded tubular braid, Nomex® brings the same properties of our series 103-013 tubular braid, with superior temperature tolerance from -60°C to +240°C. Currently available in four colors – with tracer options for easy wire bundle identification – the soft unbonded material is ideally suited for a broad range of harsh-environment applications that depend on abrasion resistance and environmental performance.

|

|

Bonded yarn, tubular braid, Nomex® brings all the same popular properties of our unbonded series 103-013 tubular braid, adding superior abrasion performance, chemical resistance, and reduced fraying and piling compared to softer, unbonded solutions. Currently available in standard black, white, and green colors, the material offers temperature tolerance in a range from -60°C to +240°C.

|

|

Bonded yarn, tubular braid, Nomex® brings all the same popular properties of our unbonded 103-013 tubular braid, adding superior abrasion performance, chemical resistance, and reduced fraying and piling compared to softer, unbonded solutions. Currently available in four colors with tracer options for easy wire bundle identification, the material offers temperature tolerance in a range from -60°C to +240°C.

|

|

Glenair offers its popular tubular braid, Nomex® non-metallic wire protection sleeving in a broad range of camouflage braidings including Desert Camo, Multicam, Battle Dress, and Winter Camo. Consult factory for availability.

|

|

Ideally suited for applications as diverse as rail transportation, marine, and military vehicles, our 102-001 and -002 polyethylene tubular braid is an economical choice with good general-purpose chemical and abrasion resistance. The monofilament material offers wide expandability for quick and easy installation over cable bundles and connectors.

|

|

102-080 Ryton is a versatile sleeving material used in mid-temperature applications. Ryton is a lightweight sleeving material with excellent chemical resistance and dimensional stability.

|

|

Glass-filled PTFE fire resistant braided shielding is ideally suited for cable protection adjacent high-heat engine application.

|