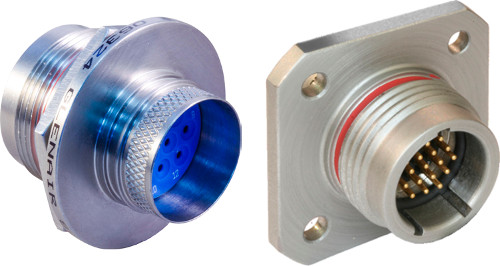

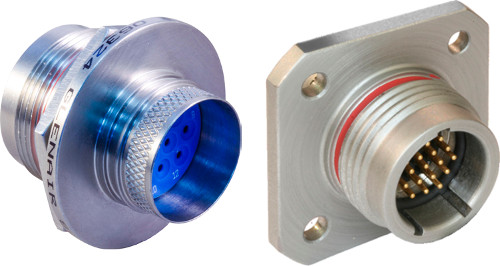

Small Form-Factor 3500 PSI Underwater Connectors

Series 802

Originally developed for petroleum pipeline inspection equipment, Series 802 connectors are available in ten sizes from 1 to 130 contacts and equipped with Viton® O-rings to withstand exposure to corrosive chemicals and high temperature environments. These connectors feature high density crimp Mighty Mouse inserts, 316 stainless steel or marine bronze shells and a piston O-ring for hydrostatic sealing. Series 802 insulated wire, panel mount receptacles can be ordered as square flange, in-line or jam-nut versions. Choose integral shield termination platform or accessory thread for use with a variety of strain relief options. Crimp style gold–plated crimp contacts accept #12–30 wire. Connectors are backfilled with epoxy potting compound. Hermetic glass–sealed connectors come with solder cup contacts (non-removable) or PC tails. 100% tested to meet 1 x 10-7 cc/sec helium leakage. Open face pressure rating of 1000 PSI, 3500 PSI in the mated condition.

Reference

Product Datasheet

Underwater / Subsea Connectors > AquaMouse™

|

- Stainless Steel or Marine Bronze Shell

Withstands corrosion in the most hostile environments. Rated for 3500 PSI when mated, these connectors are suitable for the most demanding geophysical and underwater applications.

- Gold-Plated Contacts

Attach to wire with standard mil spec crimp tools. Contacts are packaged with connectors.

- Two Shell Styles

Integral platform for direct shield attachment using Band-Master™ ATS termination system, or accessory thread for attaching accessories.

|

|

- Three Shell Mounting Options

Jam nut with o-ring for rear panel mounting, flange connector receptacle for front panel mounting, or in-line receptacles for free-hanging cables.

- Two Shell Styles

Choose the integral band platform for direct attachment of a cable shield. Install a boot, or overmold a boot over the band platform. An accessory thread is available for attaching strain reliefs and backshells.

|

|

- Printed circuit Board/ Solder cup receptacles

Feature low profile shells for minimum protrusion inside enclosures and integral standoffs for board washout. Contacts are non-removable.

- Water Immersion, Unmated

Specify 802-012 connectors for applications where open face water immersion is not a requirement. For MIL-STD-810 Method 512G immersion requirements, specify 802-030 watertight connectors . These 802-030 connectors are specially sealed ("MOD-518") and are 100% tested to maintain a helium leak rate of 1 x 10-4 cc/second at one atmosphere pressure differential from -40C to +70C.

|

|

- Series 802 Hermetic Receptacles

Feature gold plated iron alloy contacts and compression glass dielectric material. The 316 series stainless steel connector shell provides excellent corrosion protection and is suitable for e-beam welding. Viton® o-rings offer improved resistance to high temperature and harsh chemicals.

- 1 x 10-7 cc/Second Maximum Helium Leak Rate

Open face (unmated) pressure rating is 1000 PSI. When mated, Series 802 connectors withstand 3500 PSI hydrostatic pressure.

- 802-013-00 Front panel mount, jam nut receptacle

- 802-013-07 Rear panel mount, jam nut receptacle

- 802-013-03 Weld mount receptacle

- 802-013-02 Flange connector receptacle

|

|

Series 802 Hermetic Jam Nut Mount Bulkhead Feed-Thru Receptacles

Feature gold plated iron alloy contacts and compression glass dielectric material. The 316 series stainless steel connector shell provides excellent corrosion protection. Available with pin to pin contacts. Power applied to a given contact on one end will result in power to contact directly opposite, regardless of contact identification letter. Contact DWV ratings are as follows and measured pin to pin and pin to shell without breakdown: size #23 @ 750 VAC, size #20 @ 1000 VAC, size #16 and #12 @ 1800 VAC. Insulation resistance is rated at 20,000 megohms (test) @ 500 VDC minimum. Hermeticity is rated at: 5 x 10-8 sccHe/sec @ 1 atmosphere differential. 802-050 is designed to mate with Glenair 802 Series plugs. Shell sizes 5 thru 21 have a maximum open face rated test pressure of 1,000 PSI in one direction.

|

|

Overmolded AquaMouse™ cordsets are used in oil and gas pipeline equipment and other hostile environments where interconnect reliability and survivability is essential. High performance cordsets feature easy ordering and fast delivery. These fully shielded and watertight assemblies withstand abrasion, temperature extremes and chemicals. Flexible overmolding provides rugged, watertight protection to wire and shield. Two styles are available. For oil and gas equipment or continuous water immersion, choose Style 1 with thermoplastic polyurethane cable jacket and thermoset polyurethane overmolding. For non-critical general purpose applications, Style 2 cordsets with polyurethane jackets and polyamide overmolds are a good choice if cost is a concern.

- Performance Overview

- Dimensions

- With Size #23 or #20HD contacts

- With size #16 or #12 contacts

|

|

- Flange Gaskets for Series 802 AquaMouse Receptacles

These flange gaskets provide sealing between square flange receptacles and the mounting panel. Choose fluorosilicone, Viton, or neoprene material. Gaskets are .032" (0.8) thick.

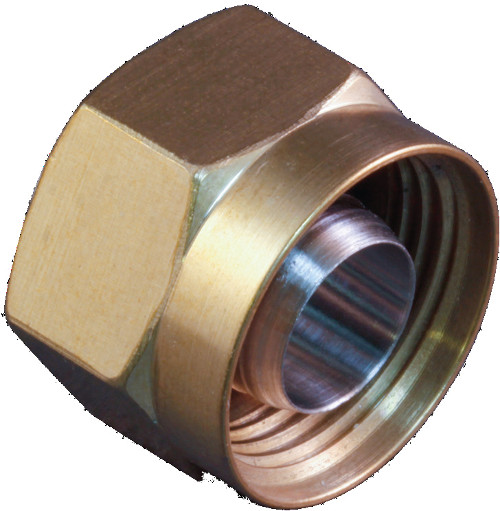

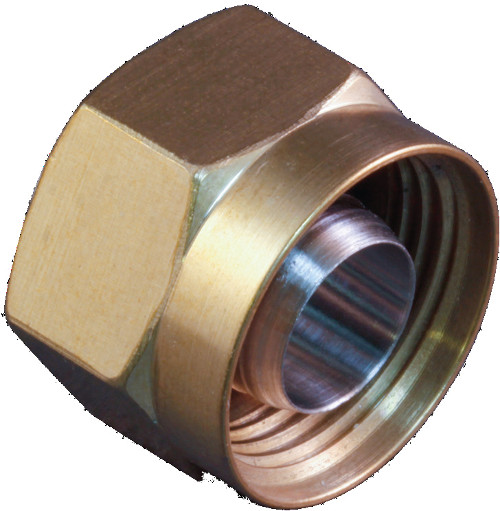

- 802 Replacement O-Rings for AquaMouse Receptacles

These Viton® O-rings fit Series 802 "AquaMouse" rear panel mount jam nut connector flanges.

|

|

- Protect Connectors from Damage

These covers prevent ingress of water and contamination. Stainless steel plug covers feature Viton® O-rings for IP68 sealing (one meter for one hour). Receptacle covers have a Viton® gasket and are made from marine bronze to minimize galling. Cover is designed for low PSI connector protection. For 3500 PSI protection, use part numbers 667-241 and 667-242.

- Three Types of Attachment Rings

Choose small diameter eye fittings for panel attachment. Larger rings fit under the jam nut or over cable jackets. Split rings can be installed on fully assembled cables.

- Polyurethane-Coated SSt Wire Rope

Offers high strength, excellent abrasion resistance and good flexibility. Or, choose Fluoropolymer jacket for high temperature exposure.

- Braided Nylon Rope

Provides excellent flexibility and good abrasion resistance, and can be ordered with slip knot fittings for easy installation on any size cable.

|

|

- Protect Connectors From Damage

These covers prevent ingress of water and contamination. Stainless steel plug covers feature Viton® O-rings for 3500 PSI sealing. Receptacle covers are made from marine bronze to minimize galling. For low-pressure IP68 receptacle sealing only, use part number 660-088.

- Polyurethane-Coated SST Wire Rope

Offers high strength, excellent abrasion resistance and good flexibility. Or, choose Fluoropolymer jacket for high temperature exposure.

- Braided Nylon Rope

Provides excellent flexibility and good abrasion resistance, and can be ordered with slip knot fittings for easy installation on any size cable.

|