Lightweight, Corrosion-Resistant ArmorLite™ Microfilament Solutions plus Industry-Standard Copper Material / QPL Straps, Joints, and Shunts

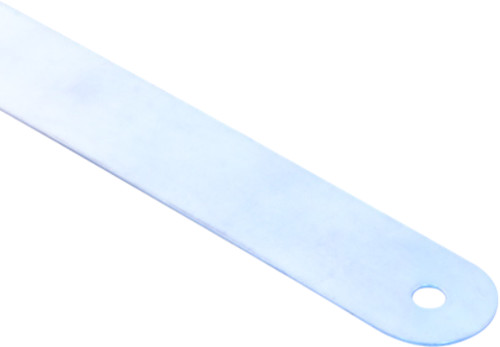

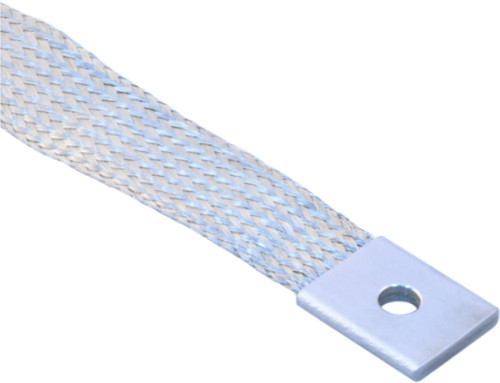

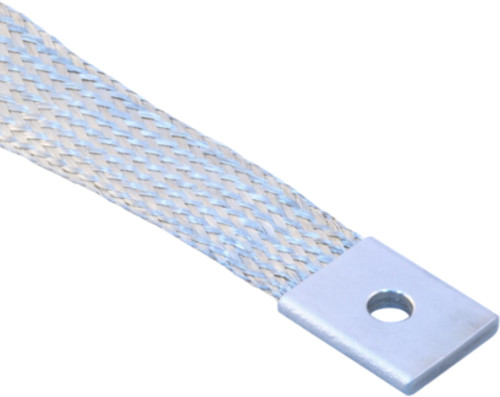

MIL-DTL-24749 Qualified Ground Straps and Ground Strips

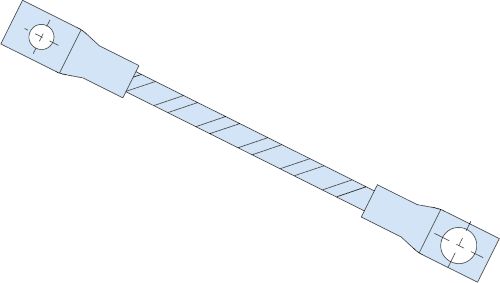

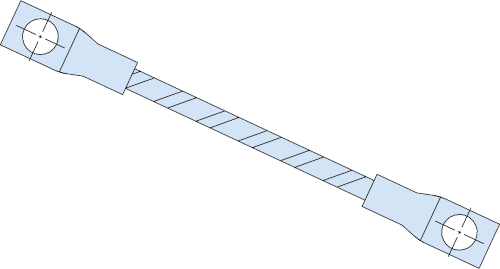

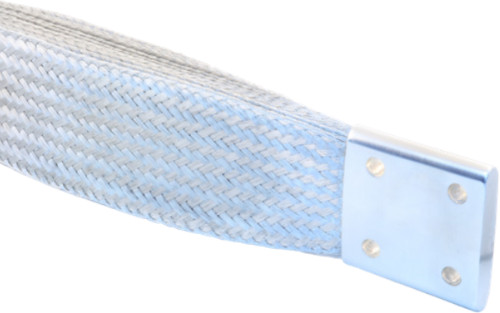

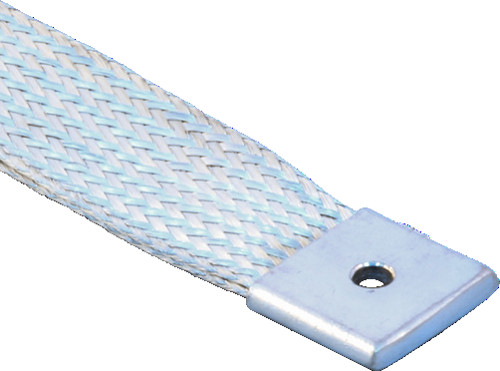

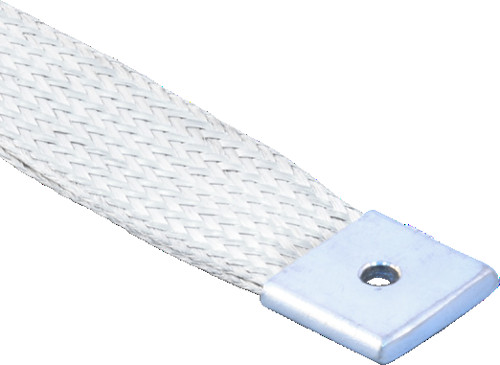

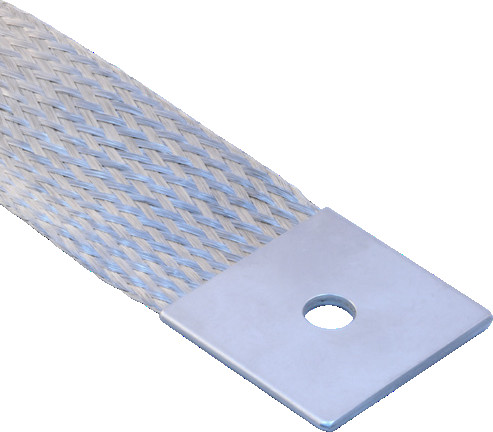

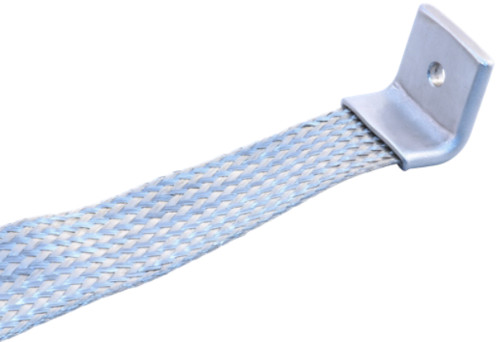

Glenair flexible braided straps are critical components in harsh sea, air, and space environments. They are used to establish reliable ground path connections, dissipate lightning strike energy, and prevent the build-up of electrostatic discharge. Special large form-factor straps are also employed in busbar applications for electrical power distribution up to 1000 Amps.

- Durable, low-resistance flexible ground straps with highly conductive or dissipative performance

- Lightweight, low-resistance flexible braided bond straps for ESD dissipation

- Flat Profile Braided Grounding Straps for optimal electrical conductivity and low-resistance performance

- Heavy-duty variants for low-voltage, high-current power distribution busbar applications

- Glenair signature and qualified military standard designs

- Round rope profile grounding jumpers with and without harsh environment insulation

Glenair supplies a complete range of lugged flexible braided bonding, grounding, and power distribution straps with lightweight ArmorLite microfilament material as well as low-resistance plated copper. In addition to high-availability catalog designs, we are also able to supply custom solutions in virtually any form factor, wire gauge, amperage, resistance, and mounting-lug configuration. Straps may also be supplied with and without insulation jacketing in wire rope (jumper) and flat profiles. Mil-qualified (QPL) straps are available for both topside and submarine applications.

Aircraft-Grade Ground Straps, Flexible ESD Bonding Joints, and Busbar Power Distribution Shunts

Glenair's complete braided ground strap capability includes high-conductivity, low-resistance grounding straps, flexible ESD bonds, and power distribution bus bars — all optimized for rugged environmental, electrical, and mechanical performance in mission-critical air, land, sea, and space applications.

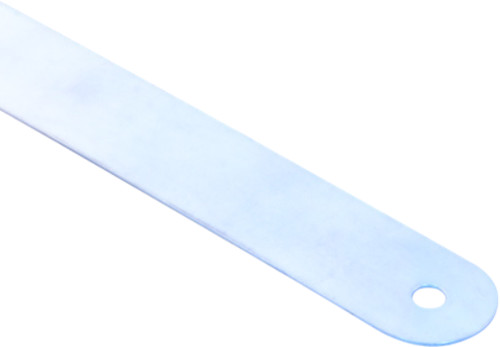

Electrical Performance Advantages of Short, Flat Ground Straps

In grounding and bonding applications, the electrical performance of a flat profile flexible braided ground strap is generally superior to that of a round profile wire rope made of the same weight of material. This whitepaper discusses the key factors that contribute to this performance difference.

Reference

- Overview: Braided Ground Straps, ESD Bonds, and Flexible Busbars

- Selection Guide: Low Resistance, Flexible Ground Straps, Bonds, and Busbars

Related Catalog

Grounding and Bonding in Aircraft

This Special Edition of QwikConnect Explores the Important Topics of Grounding and Bonding in Aircraft

Glenair QwikConnect MagazineJuly 2023Volume 27Number 3

Flexible Braided Ground Straps, ESD Bonds, and Flexible Busbars

Lightweight, Corrosion-Resistant ArmorLite™ Microfilament Solutions plus Industry-Standard Copper Material / QPL Straps, Joints, and Shunts

On this page...

- Lightweight Flexible Braided Grounding Straps and ESD Bonds

- Low-Resistance Flexible Grounding Straps and ESD Bonds

- MIL-DTL-24749 Qualified Ground Straps and Flat Bond Strips

- Ultra-Flexible TurboFlex Wire Rope Grounding Jumpers

- Flexible Power Distribution Busbars: Low Resistance, High Conductivity

- Submarine Flexible Braided Ground Straps

- Bolts, Bosses, and Lugs for Use with Glenair Braided Grounding Straps, Jumpers, and Strips

- Grounding Plate

Lightweight Flexible Braided Grounding Straps and ESD Bonds

ArmorLite Micro-Filament ESD Bonds and Ground Straps

Reference

- Overview ArmorLite™: Flexible nickel-clad microfilament stainless steel conductive braid material for ESD bond applications

- ArmorLite™ Material Comparison Matrix

|

107-105

|

|

107-106

|

|

107-107

|

|

107-108

|

Low-Resistance Flexible Grounding Straps and ESD Bonds

A-A-59569 Soft-Drawn Braided Copper Ground Straps

Tin, Nickel, and Silver-Plated Copper / Stainless Steel Designs — Commercial and Mil-Spec

|

107-101

|

|

107-102

|

|

107-103

|

|

107-104

|

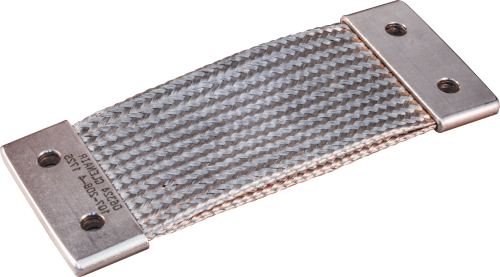

MIL-DTL-24749 Mil-Spec Ground Straps and Flat Bond Strips

MIL-DTL-24749, DETAIL SPECIFICATION: GROUNDING STRAPS AND BOSSES, ELECTROMAGNETIC, GENERAL SPECIFICATION FOR [SUPERSEDING MIL-S-24749]

Glenair Signature Designs with "Better than Mil-Spec" Configuration Options

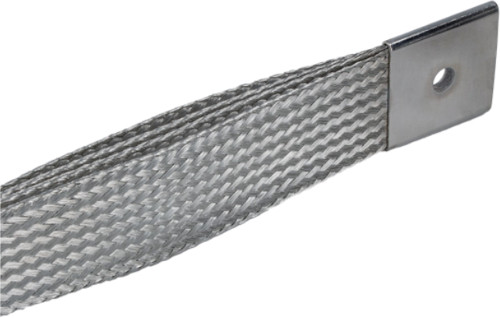

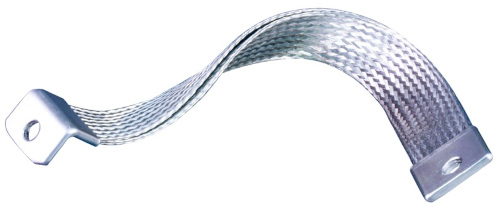

Ultra-Flexible TurboFlex Wire Rope Grounding Jumpers

360° High Flexibility

|

107-111

|

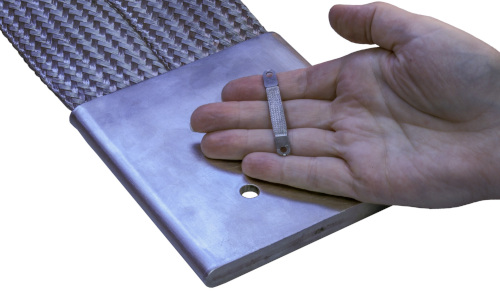

Flexible Power Distribution Busbars: Low Resistance, High Conductivity

Heavy-Duty High-Current Braided Busbar

Multi-Layer Braided Construction for Mission-Critical Power Distribution Applications

Submarine Flexible Braided Ground Straps

IAW A-A-59569

|

107-086

|

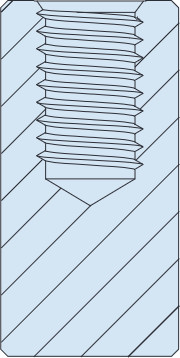

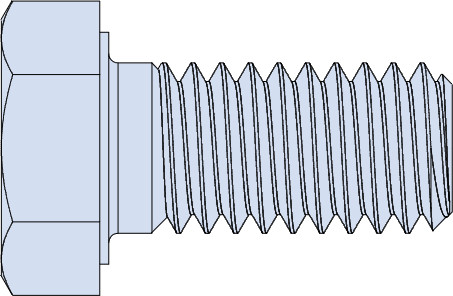

Bolts, Bosses, and Lugs for Use with Glenair Braided Grounding Straps, Jumpers, and Strips

IAW M24749

|

107-505 and 107-506

|

|

M1222 Bolt

|

|

851-005

|

Grounding Plate

|

680-162

|