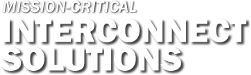

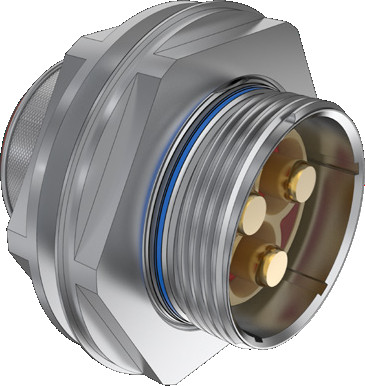

The Aircraft Industry's most Advanced Power Distribution Interconnect with High-Current Carrying Capacity Crown Ring Contacts and Flexible TurboFlex® Cabling

Series 972

Electrical power generation technology in aircraft has evolved to meet modern requirements for higher power and lighter weight systems. Growing electrical power needs on commercial aircraft — and emerging eVTOL platforms — have caused major changes in power system architectures to accommodate peakload stress factors in electrical wire interconnect (EWIS) cabling.

- PowerLoad™

High-vibration, high-temperature interconnect optimized for higher-voltage, higher-altitude, and higher-frequency. - TurboFlex®

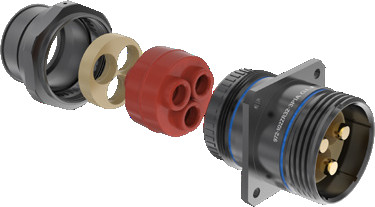

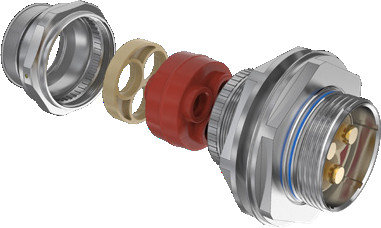

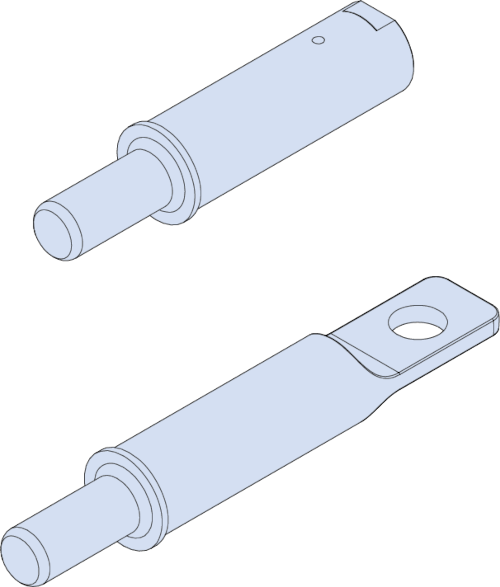

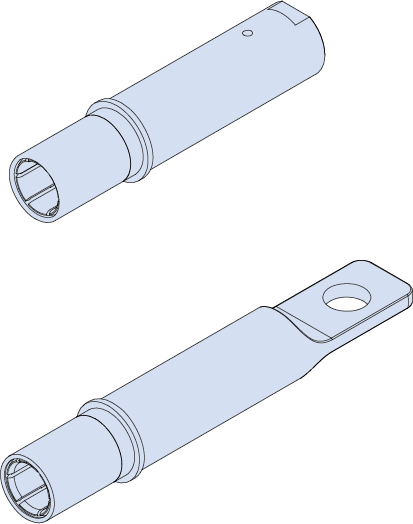

Glenair signature high-flexibility power cable solution. - Crown Ring

Crimp, bus bar, and lug style contacts, optimized for high current carrying, high temperature performance.

When specifying interconnect technology for aircraft power distribution, three main performance variables must be considered: voltage, current, and frequency. Higher voltage applications demand premium-quality insulation, careful design for partial discharge, and quality manufacturing to ensure reliable operation. Higher-current applications require detailed, peak-load analysis, accurate wire gauge selection, and high-temperature materials. Higher-frequency systems must be designed for accurate skin/proximity effect derating, incorporate comprehensive operating and peak voltage/current analyses, and perform in accordance with aircraft power generation and distribution electronics. Cable-to-contact termination must be exactingly performed to eliminate voids that can potentially initiate partial discharge events. The Glenair PowerLoad ecosystem, with its highly engineered connectors, cables, and Crown Ring contacts ensures peak performance for every specification requirement in high-current, high-voltage, and high-frequency applications.

Reference

- Overview: PowerLoad™ High-Power Aircraft Electrical Connectors

- Product Selection Guide: PowerLoad™ and TurboFlex® Solutions

- The PowerLoad™ Ecosystem

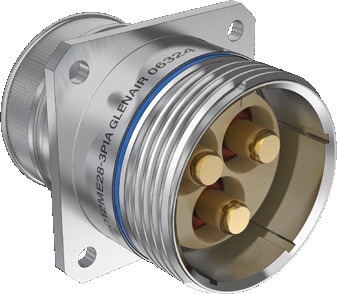

- Key Performance Attributes — Connector and Contact Exploded Views and Performance Overview — Crown Ring High-Voltage, High-Current, and High-Frequency Contact Resistance and Temperature Rise

- Performance Specifications and Test Summary

- Contact Arrangements

- Lightweight Ground Straps for Electrostatic Discharge, Lightning Strike Dissipation, and Power Equipment Grounding

TurboFlex® Cable Insulation Stripping Procedure

Related Catalogs

- Braided Ground Straps, ESD Bonds, and Flexible Busbars

- Commercial Aerospace Wire Interconnect Technologies

- EMI / RFI Braided Cable Shielding / Tubular Expandable Braided Cable Sleeving / Ground Straps

- TurboFlex® Flexible Power Distribution Cables / Series 96

PowerLoad™ High-Power Aircraft Connectors and Cables

The Aircraft Industry's most Advanced Power Distribution Interconnect with High-Current Carrying Capacity Crown Ring Contacts and Flexible TurboFlex® Cabling

Series 972

|

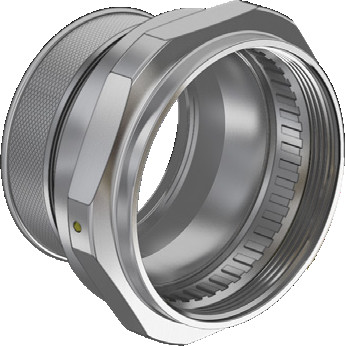

972-101

|

|

972-102

|

|

972-103

|

|

972-203

|

|

850-150 Crown Ring Crimp Pin Contact

|

|

Crown Ring Crimp Contact ToolingPneumatic Crimp Tool for #8, #4, and #1/0 Contacts |

|

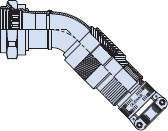

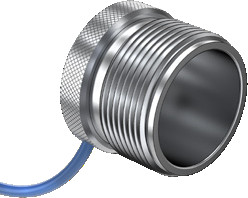

972-011

|

|

972-012

|

|

972-013

|

|

850-323

|

|

850-324

|

|

390PX055

|

|

4470PXS1128

|

|

770-001S

|

|

660-128

|

|

660-129

|

|

930-026

|

|

600-289 Connector Holding Tools

|

TurboFlex® Interconnect: Cabling with FEP and Duralectric Insulation

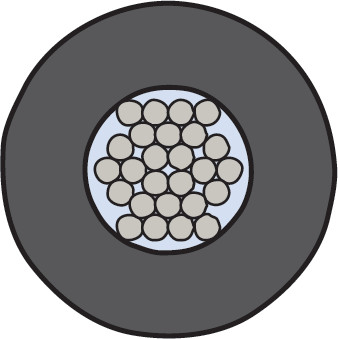

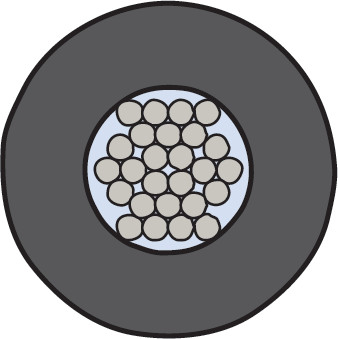

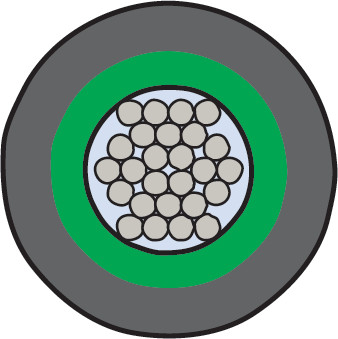

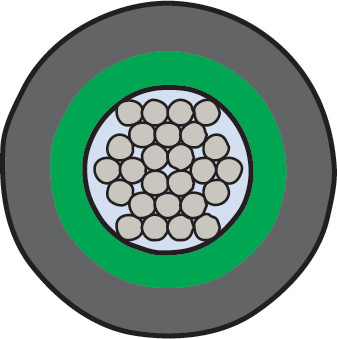

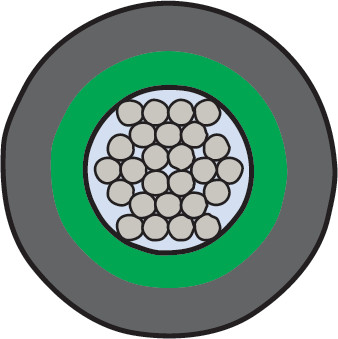

Power distribution cables present a unique challenge to electrical wire interconnect system engineers. Typically fabricated from stiff, non-flexible conductors with extremely large bend radii, such cables are heavy, hard to route, and prone to jacket damage from weathering and abrasion. TurboFlex® power distribution cables are constructed from high strand-count rope-lay inner conductors made with tin-, nickel-, and silver-plated copper. These highly-flexible conductors, insulated with FEP or Glenair signature Duralectric jacketing result in cables ideally suited for applications where flexibility, durability, and weight reduction are required.

Amazingly durable — especially in cold weather — TurboFlex cable with Duralectric insulation provides outstanding resistance to temperature extremes, ozone exposure, caustic chemicals including jet fuel, gamma radiation, and other forms of environmental and mechanical damage. Long life and performance are critical in power distribution applications. TurboFlex, with its flexible conductors and durable insulation delivers both. Consult factory for lightweight aluminum version.

About TurboFlex with Duralectric™ D Jacketing

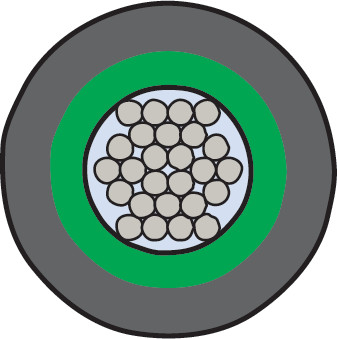

Duralectric™ D is a Glenair Signature elastomeric material used in wire insulation, cable and conduit jacketing, overmolding, and shrink boots. Glenair TurboFlex high-flexibility power distribution cables are supplied with Duralectric jacketing in different wall thicknesses, as well as "tell-tale" dual-layering.

TurboFlex core conductors are available in three aerospace-grade material and temperature configurations:

- -T = Tin/Copper (-60° – 150°C)

- -S = Silver/Copper (-60° – 200°C)

- -N = Nickel/Copper (-60° – 260°C)

A signature configuration of TurboFlex is available with high-temperature shielding and lightweight aluminum conductors.

Reference

- Overview: Ultra Flexible and Rugged Power Distribution Cables with FEP and Duralectric™ Jacketing

- PowerLoad™ and TurboFlex®: Pairing Compression Grommet Series PowerLoad Connectors with TurboFlex Wire

|

961-106-1500

|

|

961-106-2000

|

|

961-108-1500

|

|

961-108-2000

|

|

961-107-1500

|

|

961-107-2000

|

|

961-109-1500

|

|

961-109-2000

|

|

851-005

|